Printing

Where your vision starts to become a reality

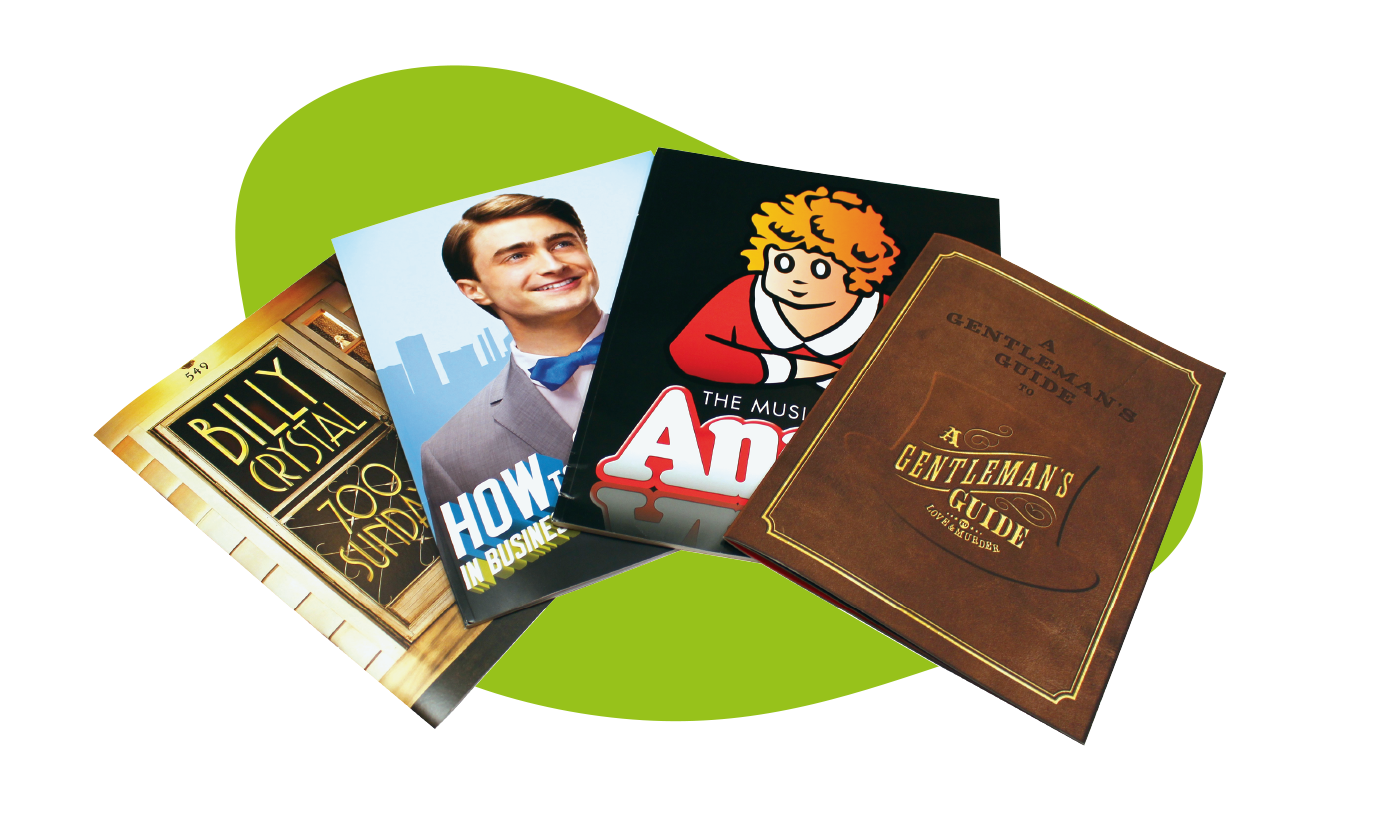

Your final product must match the proofs you approved. The colors need to be consistent and pop. The details meant to promote your brand need to be just right. The only way to achieve that is with the right printing technology in the hands of experts.

Oliver leverages leading-edge equipment in our printing systems to form the basis of our strategy and to produce your packaging, marketing collateral, and labels with perfection, every time.

Diverse press formats to fit your needs

The right printing process makes all the difference. Our pressrooms are populated with a selection of press formats and specialized capabilities to deliver a final product you’ll be proud of.

Offset Lithography

Offset lithography (or 'litho') brings your colors to life. The lithographic process captures the subtleties and sharp detailing of product packaging. Our multicolor, sheetfed offset presses can accommodate different substrates in various widths and calipers, as well as a range of inks, coatings, and inline cold foil—whether you need a standard four-color process or 8-color printing in a single pass. You also benefit from our extensive experience working with the Pantone® Extended Gamut process printing.

- Perfect for: Medium- or large-volume orders of folding cartons, marketing collateral, and posters with consistent, high-quality results

Flexography

Flexography (or 'flexo' printing) ensures consistent, high-quality results in mass-printed labels. Our 10-color narrow web presses provide swift delivery of labels on paper, paperboard, and plastic substrates. It’s cost-effective and efficient, getting printed materials in your hands faster.

- Perfect for: High-volume labels with brilliant hues

Digital Printing

Oliver utilizes state-of-the-art digital presses that feature gamut printing (using liquid ink or powdered toner) and accommodate special materials like foil or clear substrates. This is our version of clicking “File: Print,” except with the added precision of top-of-the-line resources.

- Perfect for: Short-run folding cartons, variable data printing, marketing collateral, extended content labels, instant redeemable coupons, and other labeling products on paper, paperboard, and plastic substrates.