Client Journey

Oliver is with you every step of the way.

Oliver Inc. leans on a proven printing process, from discovery to finishing, to provide creative, competitive, and reliable packaging and print solutions that drive sales and peace of mind for our clients.

Client Journey

-

Discovery

-

Design

-

Proofing

-

Production

-

Client Care

Discovery

A simple introduction goes a long way. Oliver strives to be innovative with design and pre-press concepts – and this starts with a free consultation. We listen to you to understand your goals, pain points, and ideas to find the best solutions for your packaging and print needs.

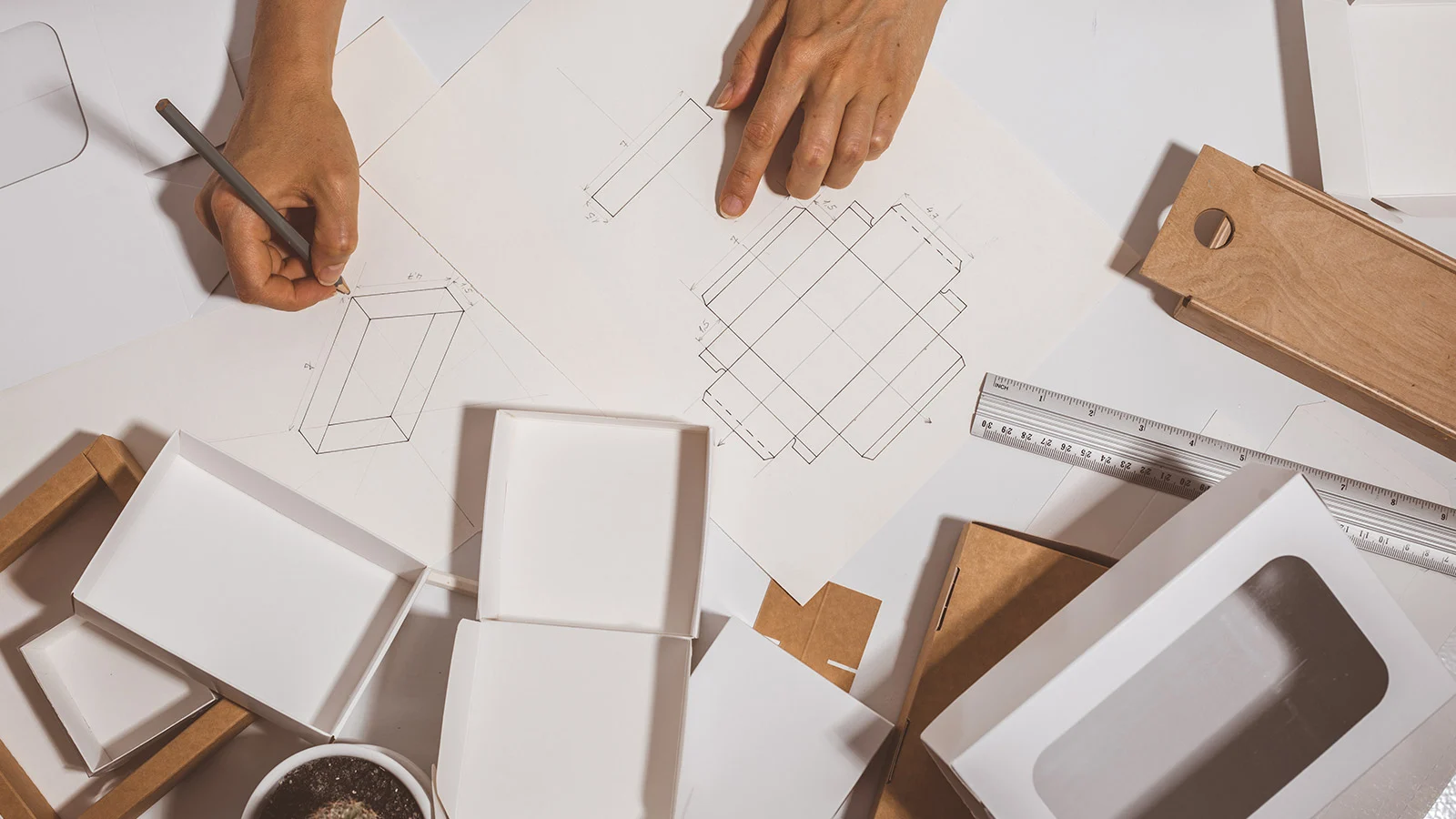

Design

Whether the solution is folding cartons, marketing collateral, rigid set up boxes or one of our other print solutions, your brand deserves a creative partner that will position you for success. Partnering with Oliver will unlock design options that help you connect with your customers at an emotional level, make a connection, and drive growth. You can rely on us for a variety of innovative design options – including coatings, inks, substrates, and more.

You’ll receive custom designs that:

- Function on all levels to protect, promote, inform, and sell

- Are made from top-of-the-line resources that are both cost-effective and eco-friendly

- Feature structures that are innovative and serve their purpose, while standing out visually

Proofing

We utilize a fully-digital workflow that provides you with a secure platform to upload your files and archive complex projects for consistent results. We can provide digital soft proofs, including 3D visualizations, to download or view online or hard proofs that allow you to touch and see your design in the adjacent formats.

For your approval:

- Standard Epson proofs

- Epson SureColor S80600 proofs with nine colors + white and silver that can output on specialty stocks

- Mock-ups to give you the feel of the packaging

- Digitally printed samples to finalize the details

Production

Oliver leverages leading-edge equipment in six production facilities strategically located throughout the United States to provide consistent quality, fast delivery, and redundancy for your print solution needs. Our goal is to provide a turnkey solution that gives you peace of mind.

We’ve got you covered:

- Offset lithography, flexography, and digital printing options

- Finishing

- Folding & gluing

- Managed inventory

- Shipping

Client Care

Oliver’s mission is to help one another so that we can make a difference for you, our client, grow together, and have fun doing it! To that end, our relationship doesn’t end when your order leaves our plants. We are always here to answer your questions, provide guidance, and, of course, discuss what’s next for you. We are building long-term client relationships.