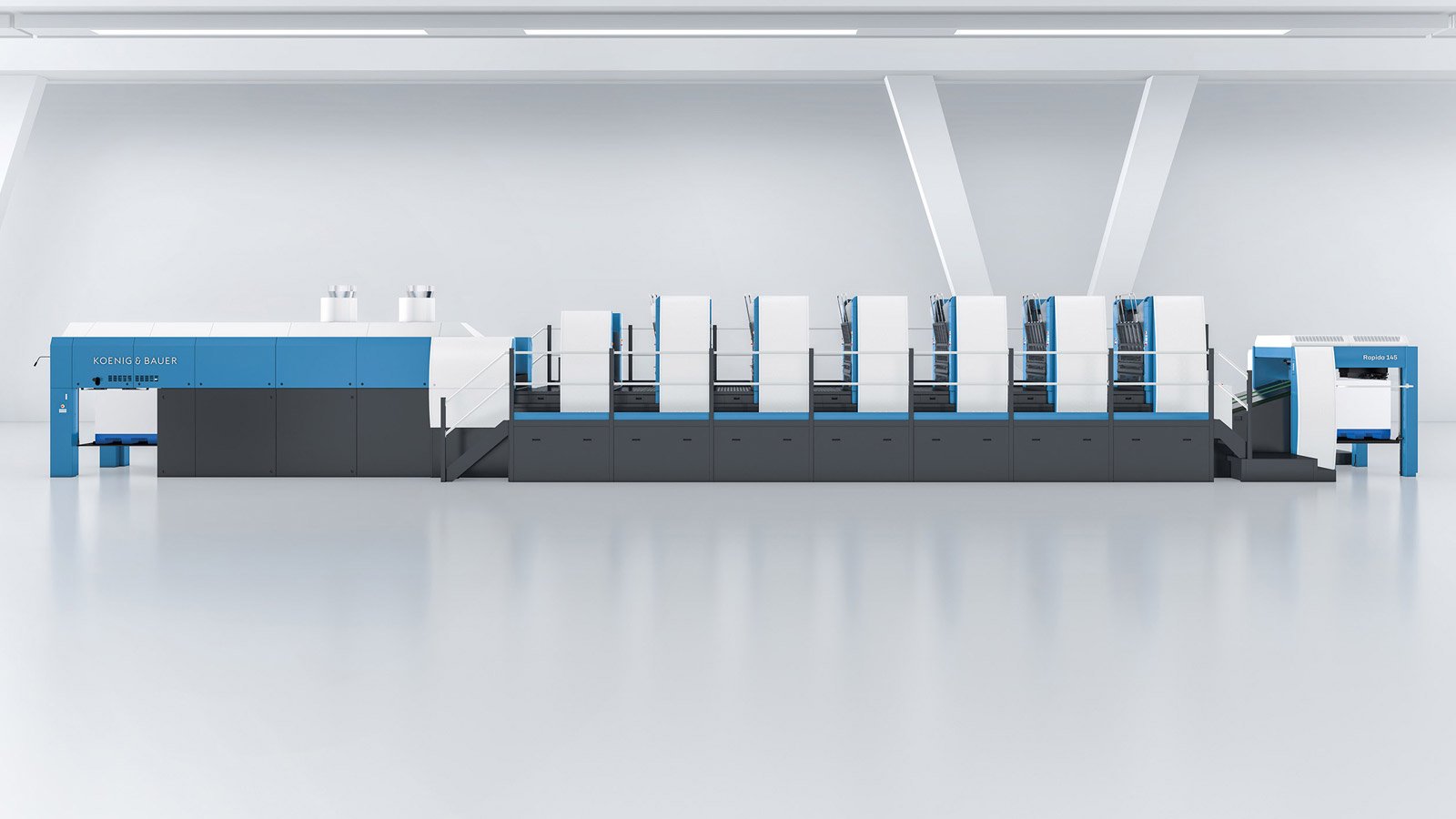

Oliver Inc. Chooses Its Ninth Koenig & Bauer Press: A Rapida 145 57-inch Seven Color

March 18, 2020

When leading food, health and beauty, and pharma manufacturers seek beautiful custom packaging for their products, they put their trust in Oliver Inc. for their print, in-store display, and package printing. This leading source of folding carton manufacturing, which specializes in these markets, not only provides sure-fire eye-catching branded packaging but designs unique boxes for convenience, ease-of-use, and regulatory standards.

“Our goal is to provide creative, competitive, and reliable packaging and print solutions that drive sales and peace of mind for our customers,“ says Dan Rodenbush, President-CEO of Oliver Inc. “In the past few years, we have invested over $20 million in capital expenditures and we continue to make investments that allow us to offer our customers a greater range of services and capabilities. With so many products on retail shelves and new products constantly being introduced, we need to support our customers with state-of-the-art equipment.“

Capacity and production will be increased by 20%

At its newly-acquired facility in Hauppauge, NY, which was formerly DISC Graphics until earlier this year, Oliver is getting ready to welcome a new piece of machinery to its pressroom this spring: a new Koenig & Bauer Rapida 145 57-inch press with UV. This new top of the line press has all of Koenig & Bauer’s latest quality, throughput and production options. It will be its most sophisticated machine when placed in operation. Plus, it will drive production and capacity by an additional 20% becoming a workhorse for Oliver’s daily production in Hauppauge and its go-to press for high end quality work. Oliver’s management team has also tallied that the new press will deliver a very cost-effective return on investment in the next several years.

“Our food, health and beauty, and pharma customers demand speed to market and a breadth of high end finishing capabilities,” says Nik Blake, Vice President/General Manager. “Strategically we felt that our new Rapida 145 57-inch seven color large format press would give us a superior advantage needed to win in today’s competitive market place. Koenig & Bauer’s leading edge technology, as well as its superior color control system will allow us to offer our existing customers the highest level of quality while also giving us the capacity to support our new business development efforts.”

Which specific features did Oliver choose for its new Rapida press?

Oliver chose the new Rapida press for its cutting-edge quality control and production functions, coupled with its extremely fast 18,000 sheets per hour running speed and enhanced makereadies. The large-format model will deliver advanced automation resulting in greater efficiency, color accuracy and quicker makeready to reduce waste. Management estimates that it will help the company grow by about 25% in the next two to three years. “This peak performing press will add at least 20% of additional capacity to our current lineup,” adds Blake. “Our demanding customers have very high industry requirements and we’ll need all of the quality control functions found on the press. These features will help ensure that we continue to provide the highest level of quality and capabilities to our growing customer base.”

One such notable feature is the new QualiTronic PDF high resolution sheet inspection system found on Oliver’s Rapida 145 press. This function, especially appropriate for Oliver’s demanding customers, runs at maximum press speed and provides the ability to inspect every printed sheet and notify the press operator of possible errors. Its camera resolution of 260 dpi permits detection of even the tiniest deviations. Detailed information on possible errors in the printed image is presented to the printer on the wallscreen of the ErgoTronic console. At the same time, errors are indicated by way of a warning lamp above the press. Error reports provide comprehensive documentation of the print quality.

Oliver specified a bundle of extensive color control options for its new Rapida. To provide the highest integrity of print available on the market, Oliver included the popular Koenig & Bauer QualiTronic ColorControl inline color control system. By automatically reading every printed sheet, the system increases speed and efficiency throughout Oliver’s workflow and provides its customers with the highest level of satisfaction. The inclusion of the QualiTronic Instrument Flight system makes Oliver one of the few printers in the U.S. with this special capability that emphasizes color balance and gray balance, taking into account more than 30 process variables. It has earned a reputation as the leading inline color control system on the market and the only system on the market that will allow Oliver’s operators to change and select the grey balance preference on press. This allows its operators to run and control the printed product to G7 standards.

Oliver’s pressroom operators, who combine 21st century mastery with old world craftsmanship, will have special registration monitoring features on the new Rapida. ErgoTronic ACR (Automatic Camera Register), a hand-held measuring device used to evaluate register marks on the printed sheets. The measurement function is integrated into the ErgoTronic console. Register adjustment is then realized automatically.

Ninth new Koenig & Bauer press

In fact, this Rapida large format press will be Oliver’s ninth machine from Koenig & Bauer. “When it comes to choosing new equipment, we make sure that we are purchasing the latest and greatest technologies available,” says Rodenbush. “Koenig & Bauer checked all the boxes with its innovative 57-inch seven-color large format press. It will help us compete in today’s aggressive environment. From the time we started researching the purchase of a new Rapida press, Koenig & Bauer has been incredibly responsive with both technical and sales information. We have had all the resources of Koenig & Bauer at our disposal and they have been amazingly responsive and easy to work with. Having such a long partnership with Koenig & Bauer, we know that it has always been a leading press manufacturer for over 200 years and it is both reliable and reasonably priced. To showcase the new press and its capabilities, we will be hosting an open house as well as making it a center point at our upcoming trade shows.”

About Oliver Inc.

Headquartered in Twinsburg, Ohio, Oliver Inc. is a leading provider of highly customized, quick turnaround, packaging and marketing collateral solutions. Oliver has made significant investments in modern equipment, facilities and people. Known for its white-glove approach to customer service, the company provides a turnkey platform from design to fulfillment, simplifying complex requirements with consistent on-time, on-budget, ultra-high quality products and services. www.oliverinc.com

About Koenig & Bauer

Koenig & Bauer (US) is located in Dallas, Texas and a member of the Koenig & Bauer Group, which was established over 200 years ago in Würzburg, Germany. Koenig & Bauer’s claim, “We’re on it.” gets to the heart of Koenig & Bauer’s values and competencies for all target groups. The group’s product range is the broadest in the industry; its portfolio includes sheetfed offset presses in all format classes, post press die cutting, folder gluers, inkjet presses and systems, flexographic presses, commercial and newspaper web presses, corrugated presses, special presses for banknotes, securities, metal-decorating, glass and plastic decorating. For more information visit the company’s web site at www.koenig-bauer.com

For additional information, contact Doug Doroh at ddoroh@oliverinc.com or call 330.425.7890